CE Cleanrooms focuses on delivering turnkey controlled environments for the industrial and manufacturing sectors.

These specialized facilities limit the exposure of sensitive production processes to contaminants that affect the performance, quality, lifespan and safety of the product.

Although these controlled environments have many features in common, the precise requirements vary considerably from one cleanroom project to the next. For example, while both have rigorous compliance standards, aerospace and food manufacturing cleanrooms have significantly different specifications. So, we begin each project with a consultative session to discuss your needs.

This requirement-gathering conversation covers everything from standards and regulations to brands and products and whether modular and pre-engineered materials suit your project, budget and timeline.

Cleanroom Classifications & Regulations

CE Cleanrooms has extensive expertise in cleanroom regulations and standards across various industries.

Our clients depend on us to ensure that their finished project meets all requirements for proper design, monitoring and control of manufacturing processes, facilities and more.

Industry requirements

Relevant ISO classification and standards

FDA-mandated cGMP regulations

Click images to enlarge

Cleanrooms for Manufacturing

Controlled manufacturing environments provide ideal conditions for making products with sensitive components or strict industry regulations.

CE Cleanrooms' Experience with Controlled Environments for Manufacturing

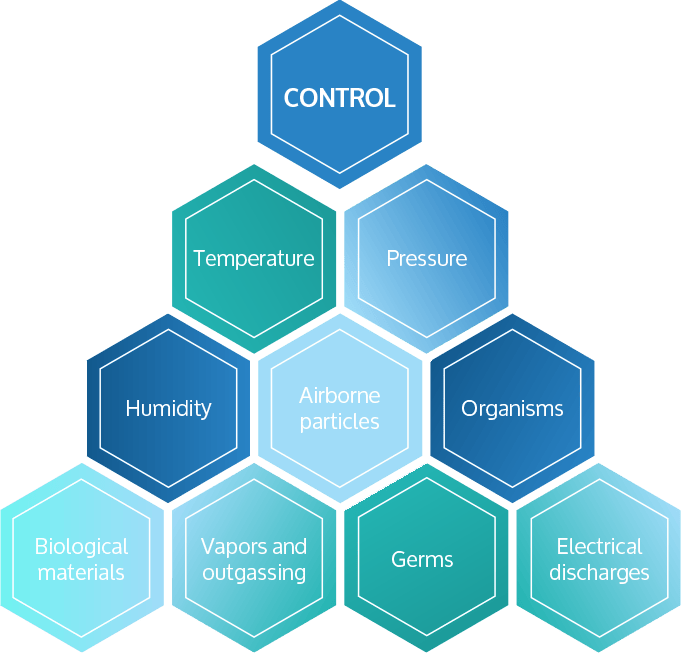

We design and build facilities that minimize contaminants such as dust particles, germs, chemical vapors and other pollutants entering, circulating and escaping from the cleanroom enclosure. Depending on the application, we may also install equipment to control air pressure, temperature and humidity.

Most manufacturing facilities are ISO classes 7-8. However, food processing facilities are usually ISO 5-7.

Below are some of the different types of manufacturing facilities we build:

Automotive

These cleanrooms are generally for manufacturing electronics and precision parts and providing enclosures for finishing processes such as spray painting.

Aerospace

These are facilities where delicate parts, hardware, electronics and optics are built. They must meet ISO class 7 and comply with the American Society for Testing and Materials (ASTM) and National Aeronautics and Space Administration (NASA) standards relating to air filtration and procedures.

Food

These environments are designed to minimize exposure to germs and fungi and increase shelf life. They must meet ISO 5-7 and include temperature, humidity and air filtration systems.

Injection Molding

Cleanrooms are needed to eliminate the danger of particle contamination during the production of plastic parts. However, ISO compliance varies depending on the industry, with health care applications requiring the most stringent standards.

Medical Cannabis

Typically, cannabis grow rooms are ISO 5-7 and comply with FDA’s cGMP regulations. Primary concerns include reducing the risk of pollen contamination between strands and limiting mites and other microbial contamination.

Positive & Negative PSI Rooms

Positive PSI rooms prevent contaminants from entering, while negative PSI spaces keep contaminants contained within the work environment.

White Rooms

We offer spaces for tasks such as packaging and assembly that don't require certification.

Electronics Cleanrooms

From semiconductors to microchips and nanotechnology to optics, the electronics industry uses cleanrooms to limit pollutants and control humidity, temperature and airflow within production, assembly and research spaces.

CE Cleanrooms' Experience with Electronic Cleanrooms

The CE Cleanrooms team has the advanced skills to design and build cleanrooms for the electronics industry.

Here are some of the projects we’ve worked on in the past.

Optics

Manufacturing spaces for the lenses used in cameras, telescopes and other optical equipment require contamination, humidity and vibration isolation controls. Spaces are typically ISO 5-7 cleanrooms, with the critical work performed under Laminar Flow ISO 4 Benches.

Semiconductors

Even the tiniest speck of dust can damage delicate semiconductors and chips used in cell phones, computers and other electronic devices.

Semiconductor cleanrooms are sterile and enclosed environments located within semiconductor foundries or fabs[DB1] . We use state-of-the-art cleanroom technology to tightly control airborne particulates, air pressure, airflow, static, vibration, lighting, temperature and humidity.

Nanotechnology

Nanotechnology cleanrooms require environments free from particles, gasses and other contaminants that could adhere to components during manufacturing and impact product quality and performance. Nanotech is used in semiconductor, optics, medical device, pharmaceutical delivery systems and other industries.

Fuel Cell Battery Dry Rooms

These cleanrooms feature highly specialized dehumidification equipment to prevent chemical reactions, corrosion and a reduction in the performance and lifespan of lithium batteries. Relative humidity levels may be as low as one percent in these facilities.

We have completed a number of these projects specifically designed to meet the needs of research and development teams as well as component manufacturing and assembly.

Controlled Environments for Life Science & Biotechnology

Cleanrooms in this category facilitate the study of living organisms in the fields of biology, biochemistry, genetics and microbiology. They typically feature one- or two-person suites with strict controls for cross-contamination and separation that allow the science to be the only variable.

CE Cleanrooms' Expertise in Cleanrooms for Life Science and Biotech

The specifications for life science and biotech cleanrooms vary considerably from one application to the next. We generally design and build these cleanrooms using pre-engineered wall components. We customize the electrical, HVAC, air filtration, lighting and control systems for the room’s type, size and use.

Below are some of the life science and biotech cleanrooms in our portfolio.

Bioprinting

Bioprinting is a technology in which bio-inks, mixed with living cells, are printed in 3D to construct natural tissue-like three-dimensional structures. This technology is currently used in various research areas, such as tissue engineering and new drug development. Environments are rigorously controlled for temperature, contaminants and airflow.

Environmental Testing Rooms

Also called an environmental chamber, a climatic chamber or a climate chamber, an environmental testing room is an enclosure in which temperature, humidity and other variables are managed. This allows scientists to test the effects of different conditions on industrial and biological products, materials, electronic devices, food and more.

In addition, testing in an environmental chamber may include chemical, bacteriological and radiological analyses of water, soil, animals, air and hazardous waste.

Some chambers can also test the effects of corrosion by simulating it with salt spray. Testing rooms must comply with ISO/IEC 17025 standards and maintain a cleanroom classification of ISO Class 5/Federal Standard 209 Class 100.

Laboratory, Research & Development

This category comprises a wide range of cleanroom types across many industries. They are isolated spaces focused on maintaining a low concentration of contaminants such as dust, vaporized particles and organisms.

We have built several highly specific controlled environments for research and development teams and laboratory applications.